Willi Schüler GmbH is a major German player in the world of

oils and industrial lubricants, taking care of everything from machinery to cars and tractors. Based in Ebringen, Germany, they’re the go-to distributor for

Fuchs machinery lubricants and their own brand,

oelluxx, offering every type of machinery oil you could need. With a product lineup of

over 38,000 items, the company runs

two e-commerce platforms for both B2B and B2C clients and is developing a third one for B2B customers.

Looking for ways to enhance their operations, Willi Schüler upgraded its

ERP system from Microsoft Dynamics NAV 2009 to Business Central in 2023. This shift called for a new

Product Information Management (PIM) solution, leading them to partner with us at Allium for Pimics, a fully integrated PIM solution for Business Central. This case study walks you through the entire implementation process, the hurdles we’ve overcome, and the exciting benefits Willi Schüler gained down the road.

Challenges in the Rearview

Before integrating Pimics, Willi Schüler was navigating a maze of product data challenges:

1. Fragmented Data Management

With nearly 40,000 products, each with countless attributes (sizes, types, images, descriptions), and varying B2B/B2C needs, Willi Schüler had

product data scattered across multiple Excel sheets. Finding the right info felt like searching for a needle in a haystack, making data accuracy and consistency a real challenge.

2. Manual Updates Across Platforms

Updating product data across the

ERP, marketing, and e-commerce platforms was a tedious, manual job, a bit like trying to plug leaks in a boat while still in the water. It was slow, error-prone, and led to inconsistencies, delays, and wasted time.

3. Lack of Structured Processes

There was no unified system in place for handling product attributes, images, and translations across various e-commerce platforms. Each platform resembled a separate island and there were no bridges connecting all the islands — processes were managed in isolation, making it tough to maintain smooth & effective workflows.

4. ERP Transition Complexity

The

migration from Microsoft Dynamics NAV 2009 to Business Central added another layer of complexity. All product data had to be restructured to be compatible with the new system, turning the transition into a massive undertaking.

5. Integration with Shopware 6

Lastly, Willi Schüler needed

a direct connection between Pimics and their Shopware 6 e-commerce platform. This custom integration became the final piece of the puzzle — challenging but essential for syncing all product data across systems. It enabled seamless data synchronization, ensuring that product information remained consistent and up-to-date across all platforms.

Building Bridges in the Data Tide

When Willi Schüler decided to implement Pimics, they were looking for more than just a new system — they needed a lifeline to organise the chaos of their product data. The solution? A fully integrated PIM system, embedded in Microsoft Dynamics 365 Business Central, providing

a single source for product information and DAM. This not only streamlined their data but brought consistency and efficiency across the board. Key features included:

- Automated synchronisation of ERP data with Shopware 6.

- Streamlined management of attributes for both B2B and B2C products.

- A significant improvement in data consistency across all platforms, reducing redundancy and errors.

Laying the Foundation: Initial Evaluation

At the heart of every implementation process is a primary evaluation phase, where every product data detail is examined, categorised, and sorted. It’s not just about setting up the system, it’s about making sure everything is properly structured and ready for seamless integration into Pimics.

This evaluation phase is often an eye-opener for clients. A tool like Pimics provides valuable insights into potential areas of improvement. The team benefits from expert guidance while the company gains a fresh perspective on their workflows.

Here are the key steps in the evaluation process:

- Data structure and workflow analysis: We started by taking a close look at Willi Schüler’s product catalog, understanding how their data was organised and how it flowed through the business.

- Identifying data gaps and inconsistencies: We pinpointed where data didn’t match across platforms and highlighted areas that needed improvement.

- Creating a tailored strategy: We developed a customised data management plan to improve processes and boost efficiency.

- Preparing for integration: We also made sure their ERP and e-commerce systems were ready for a smooth integration.

This phase gave us

much-needed insights and an

actionable roadmap for optimising data management before rolling out Pimics.

The Implementation Journey

Originally planned for summer 2023, the ERP transition took longer than expected, due to the complexity of migrating data from the old ERP to the new one, while maintaining data integrity, compounded by Business Central’s frequent updates.

Once the ERP system was in place, we turned our focus to Pimics implementation. Key goals included:

- Consolidating all product data into a single system: This entailed collecting data from hundreds of Excel files and streamlining them into Pimics.

- Automating data synchronisation across all platforms: Ensuring that every update in one system is reflected across the entire network.

- Providing distinct attribute structures for B2B and B2C products: Tailoring the system to support both business models.

- Integrating Pimics with Shopware 6: A groundbreaking task which involved a lot of coding, testing, and fine-tuning to make sure everything ran smoothly.

Impact on Business Operations

Since adopting Pimics, Willi Schüler has streamlined operations, improved data accuracy, and automated key workflows. Here’s how it’s made a difference:

- Centralized data management: A single source of truth for all product information, eliminating inconsistencies.

- Automated updates: Changes in the ERP system instantly sync with e-commerce platforms.

- Improved workflow efficiency: Less manual work means quicker product updates and fewer errors.

- Built for growth: The system is ready to support expansion, including the planned third B2B e-commerce platform.

- Better customer experience: Accurate, well-organised product data ensures a smoother shopping journey for B2B and B2C customers.

"

Thanks to Pimics, we have been able to manage our product data efficiently and centrally. Every change is automatically integrated into our sales and marketing channels, which saves a lot of time and improves data consistency," said Tobias Rösch, Head of Product Management at Willi Schüler.

It’s also worth mentioning that

product data sheet management (

Datenblattverwaltung) has significantly improved, addressing a key challenge in maintaining accurate and up-to-date product information everywhere. This shift helped reduce errors and accelerate product data updates.

Key Takeaways

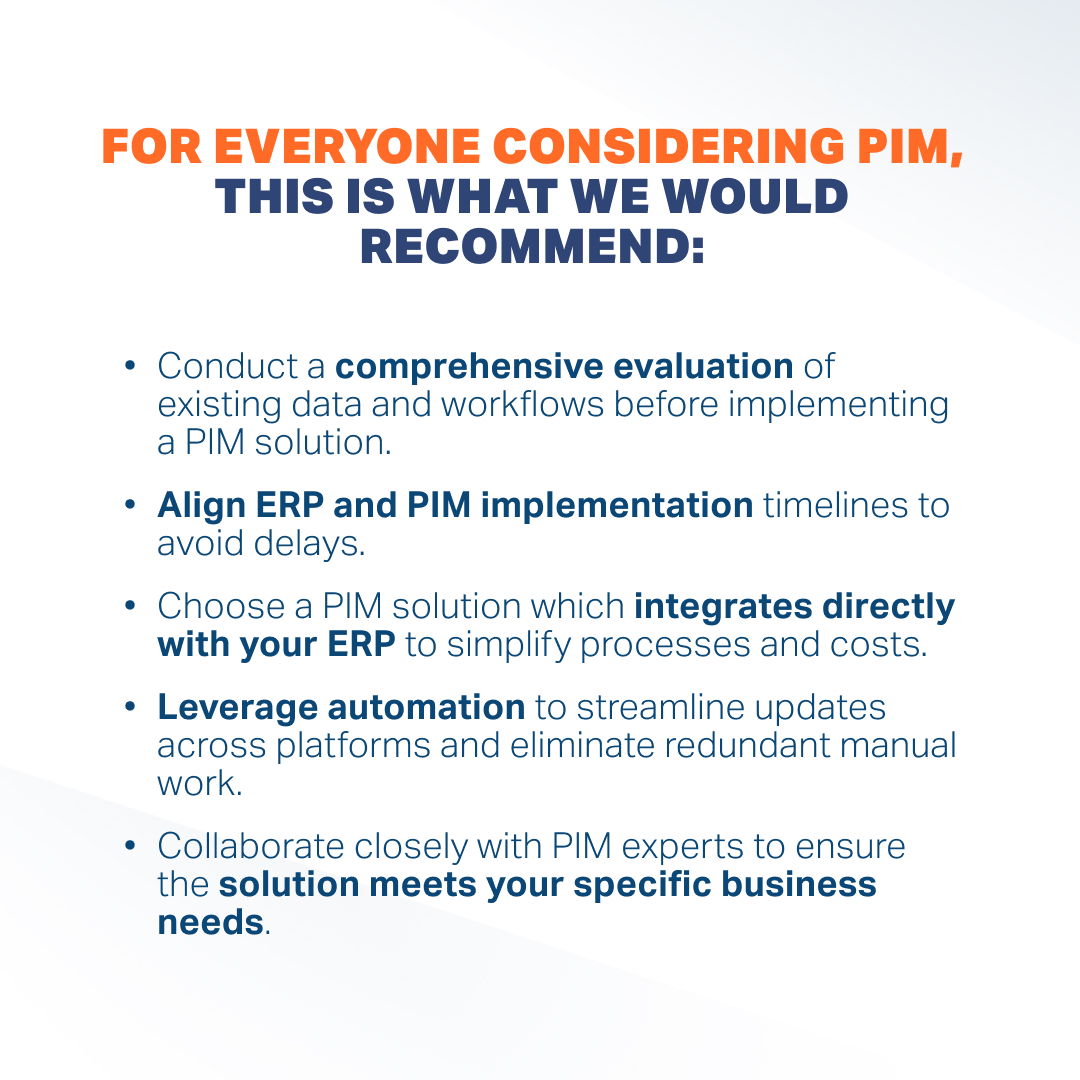

Switching to a new ERP while setting up a PIM takes careful planning and flexibility. Custom integrations, like the Shopware 6 connector, need thorough testing to run smoothly. But a well-structured PIM makes a huge difference — boosting data accuracy, streamlining operations, and setting you up for future growth.

Looking Ahead to Next Features

The next phase in the implementation process will involve integrating a label printing system using EasyCatalog for Adobe InDesign. This will allow Willi Schüler to generate product labels directly from the ERP system, streamlining processes and reducing manual work even further.

Final Thoughts: A Success Story of Transformation

Willi Schüler GmbH and Allium teamed up to streamline product data with a successful Pimics implementation.

What was once a manual, scattered process is now an automated, centralised system. Despite challenges with ERP migration and custom integrations, this project set the stage for future growth. With more accurate data, the company is ready to meet B2B and B2C demands while running more efficiently than ever.